The future of flat pack

Flat pack furniture has been around forever and often gets a bad press, being associated with cheap design and poor quality.

However the evolution of new technology has breathed new life into the concept and rather than being seen as a tired and old-fashioned type of furniture, flat pack could well hold the key to the future.

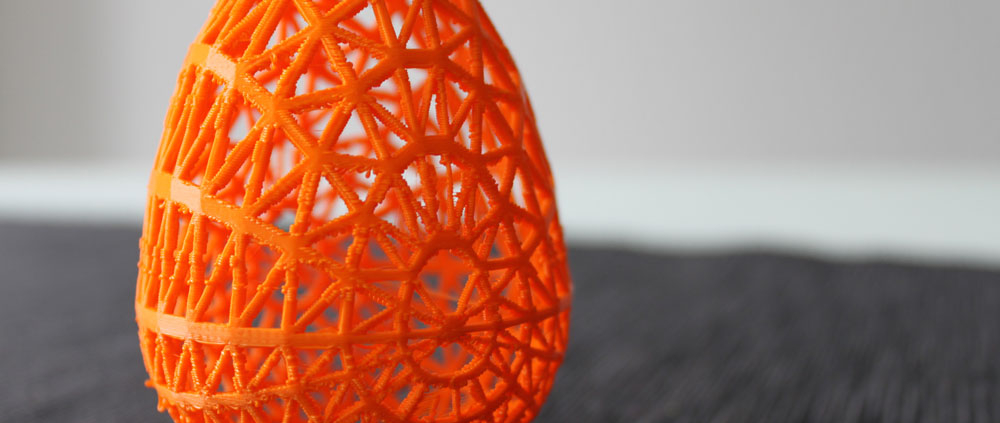

In recent months, 3D printing has been in the headlines more often than it’s been out, offering possibilities and capturing the public’s imagination in a way never before seen. And it’s the combination of 3D printing and CAD design coupled with flat pack that’s providing an entirely new vision for the future.

We take a look at the future of flat pack and ask whether it could really be possible to design your own home in this way?

What is 3D printing and CAD design?

CAD design is a process often used by architects and interior designers that allow them to recreate an environment in a virtual 3D form.

This type of software allows every aspect to be manipulated and tweaked to ensure that the final design is absolutely perfect and doesn’t contain any unwanted surprises.

Kitchen design is often completed using CAD software, allowing the designer and the customer to work together to create a finish which delivers on every level.

3D printing combines perfectly with CAD design, although at present it’s more frequently used for smaller applications. Nevertheless, the technology is there for any design to be converted to a compatible file type and then read and “printed” using a choice of materials to create a strong, durable and accurate 3D design.

3D printing doesn’t have the same limitations as traditional engineering and it’s possible to create far more intricate shapes and designs than could have been achieved in the past. This flexibility of design eradicates the need for vulnerable joints and hinges and allows the final product to be far stronger than could have been previously produced.

How it could work

Homes have already been created using 3D printing technology so there’s no doubt about whether the concept is possible, it’s just how it could work in practice.

In theory the idea could be very straightforward as the designers already have the necessary skills from their experience in working with CAD software for other housing projects. However, rather than simply recreating the perfect kitchen, designers and architects would design an entire house.

And just like the present CAD design process used on a smaller scale, this would allow potential homeowners to be far more involved in the final result. From deciding where to put plug sockets to the number of bedrooms, customers could create their own home to meet their requirements without the huge expenses which currently are unavoidable for those who want to have input into the design.

These final CAD designs could easily be converted into a flat pack model which could be quickly and easily erected, saving thousands of pounds and months’ worth of construction.

Is this the future?

Although the technology is currently available, it’s likely to take some time before the idea becomes a wide spread reality for most home owners.

As 3D printing continues to expand and grow the possibilities for practical design will continue to increase as well, and will gradually become a more mainstream idea, rather than a rather unorthodox alternative.

One of the benefits of this concept is that housing could be designed, created and constructed within a very short space of time. For those areas which are suffering from a dire shortage of housing, perhaps this solution might be the way forward…?

Only time will tell for certain but keep a look out for some creatively designed new housing popping up any time soon…