3D Printing and the ‘Citizen Supply Chain’

Due to the patchy and inconsistent supply of critical PPE to the NHS there have been many frontline and keyworkers put at unnecessary risk since the outbreak of the covid-19 pandemic.

These critical staff have had to turn to the public to provide them with the lifesaving PPE equipment that could not be sourced or procured easily.

Who needs these shields and how can I help?

Keyworkers and frontline NHS staff and Pharmacists are in need of these shields and over 600,000 have been ordered from Charity groups although to date only 168,000 have been made and delivered to these key people. If you have a 3D printer at home or office then you could very quickly become a donor of these lifesaving devices. There are some sanitisation steps required and a quarantine period will need to be observed but this is a necessary precaution to prevent the spread of Covid-19.

If you can’t help by producing items, you could consider donating to the GoFundMe Campaign:

https://www.gofundme.com/f/3dcrowd-emergency-3d-printed-face-shields

Can you organisation benefit from fast CAD services?

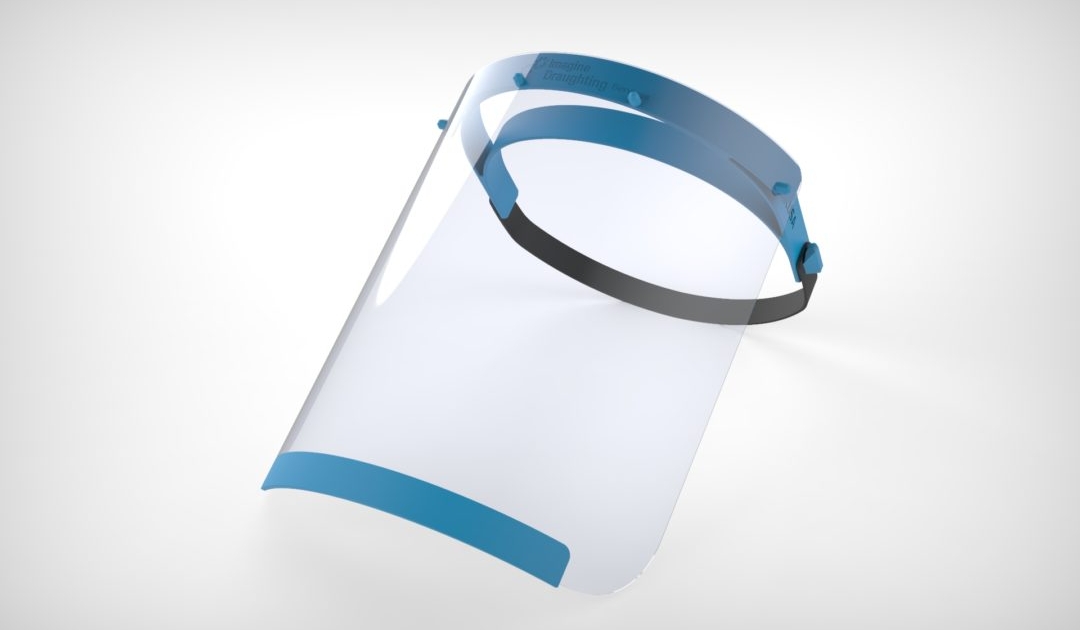

As a group of talented freelance staff, we are able to turnaround bespoke designs and have drawings ready for manufacture or prototype in a matter of hours. For example the image you see above was designed and rendered in less than half a day.

More information can be found here including print files and all sterilisation techniques recommended.

https://3dcrowd.org.uk/wiki/docs/

Material Selection and Print Technology

The most common and the more cost effective print technology being used the manufacture the shields is FDM (Fusion Deposition Modelling) as it provides low cost items with minimal clean up and speed of print.

Other technologies such as SLA and SLS printing are more expensive and usually print times are longer. These technologies are more suited to high resolution and resilient components that may be used to mimic manufactured plastic components.

Shields can be printed using a 3D Printer and be ready to use in combination with Acetate sheet and Elastic Webbing in a few hours.

The visor components can be produced using PLA Filament if it will be a single use item, if you need to sterilise and re-use then PETG Filament is recommended.