How a 3D CAD Design can save you time and money

Today engineers face a number of different challenges including complex designs, demanding clients and low production budgets. Thankfully, they have tools at their disposal that enable them to overcome these challenges, one of which is 3D CAD design.

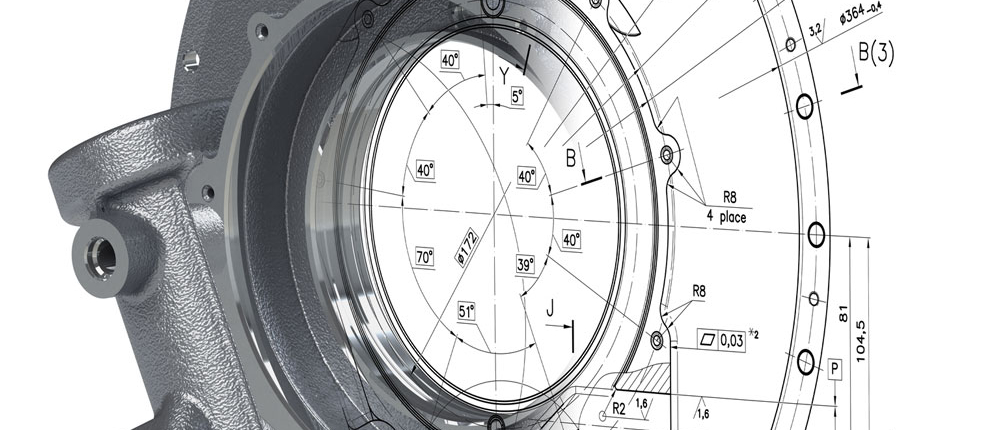

3D CAD design is a type of computer software that allows engineers to build up 3D virtual models of their product design. It provides a wide range of benefits and opportunities, some of which we have outlined below.

Testing engineering projects

3D CAD design software provides unprecedented insight for engineers when creating new designs. It gives them the ability to thoroughly test their designs, before putting them into production.

If an engineer is looking to experiment with a new design that hasn’t been made before, they can use 3D CAD software to do it. They will be able to build up the product on screen so they can get a clear and realistic view of it, before they have even spent any money on materials.

It is a much quicker form of prototyping, as you do not have to physically manufacture the product. You can simply build a virtual version of it in a fraction of the time!

Identifying and solving problems

If there are any problems with a design, the 3D CAD software will highlight them to the engineer, so they can quickly fix the issue and make the necessary alterations. It prevents engineers from putting a product into production that has weaknesses, which could cost businesses a significant amount of time and money.

With 3D CAD design, there is no need to worry about wasting your time and money on an inferior design. You will have the opportunity to see the end result before it’s even built, allowing you to correct any issues before it’s too late!

Reducing material wastage

3D CAD design can inform engineers exactly how much of each material they are going to need to manufacture their design. This information can then be passed onto to the buyers and manufacturers to ensure they don’t over order or over use materials.

When it comes to manufacturing products, every penny counts, so by getting accurate material measurements, businesses stand a good chance of being able to keep material wastage and costs to a minimum.

Minimising manufacturing time

The more detailed a plan is the quicker a product can be manufactured. Engineers that use 3D CAD software as part of the design process can ensure they measurements are 100% accurate, so that fewer mistakes are made during the manufacturing process.

The quicker a design can be manufactured, the less a company will have to spend on labour and overtime.

Speeding up time to market

No matter what industry they work in, engineers are required to get the parts or products they are manufacturing ready as quickly as possible in order to beat their competition.

By using 3D CAD software, engineers can essentially speed up the design, testing and manufacturing process, allowing them to get their products to market much quicker.

Prevent re-calls

Product re-calls not only cost businesses time and money but they can also cost businesses their reputation. Thankfully, engineers that use 3D CAD design software have the opportunity to minimise the chances of product re-calls through a comprehensive testing process.

In such competitive times, it is crucial that engineers design and manufacture products in the most efficient way possible. By using 3D CAD design, they are able to minimise material wastage, identify and solve problems and reduce manufacturing time, allowing them to stand the best chance of beating their competitors and releasing high quality products into the market. Contact us today for advice on how we can help support your project.