3D Rendering vs Product Photography

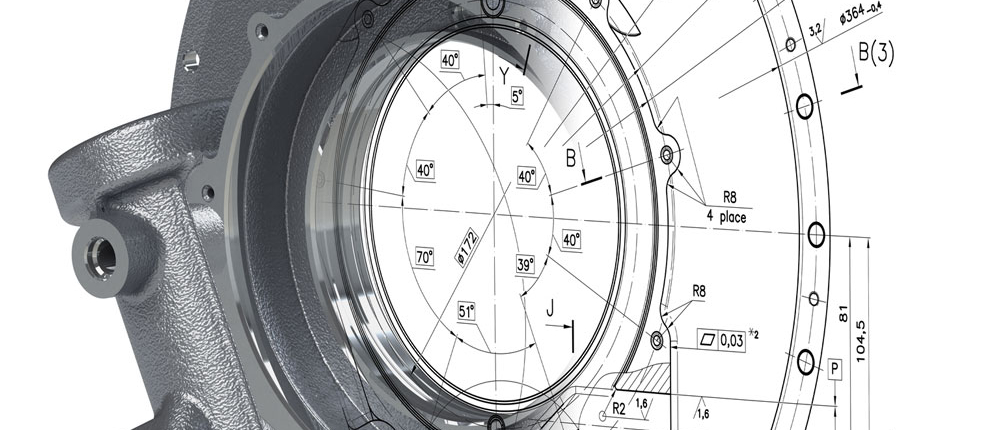

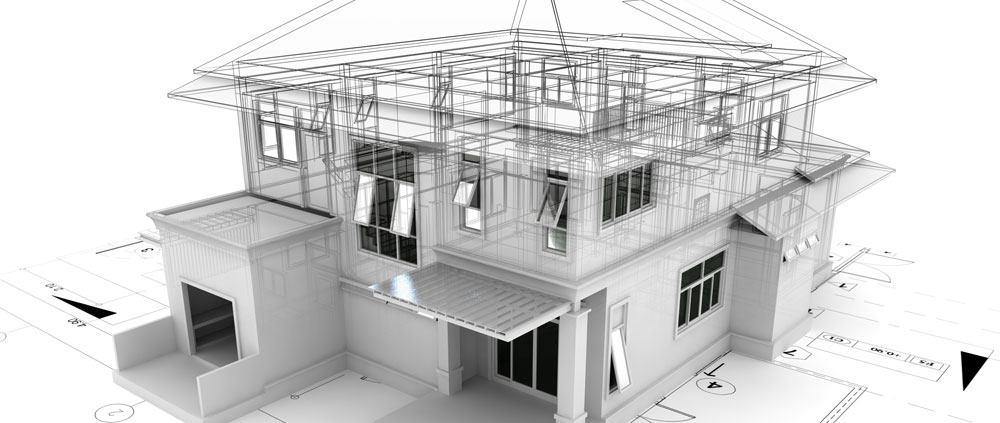

What is 3D Rendering?

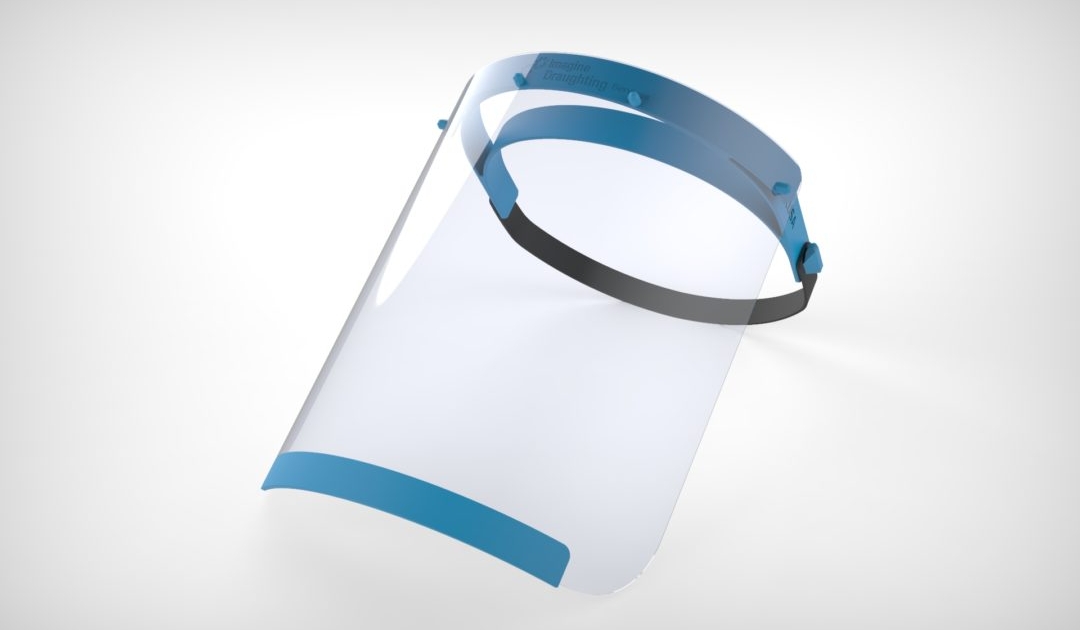

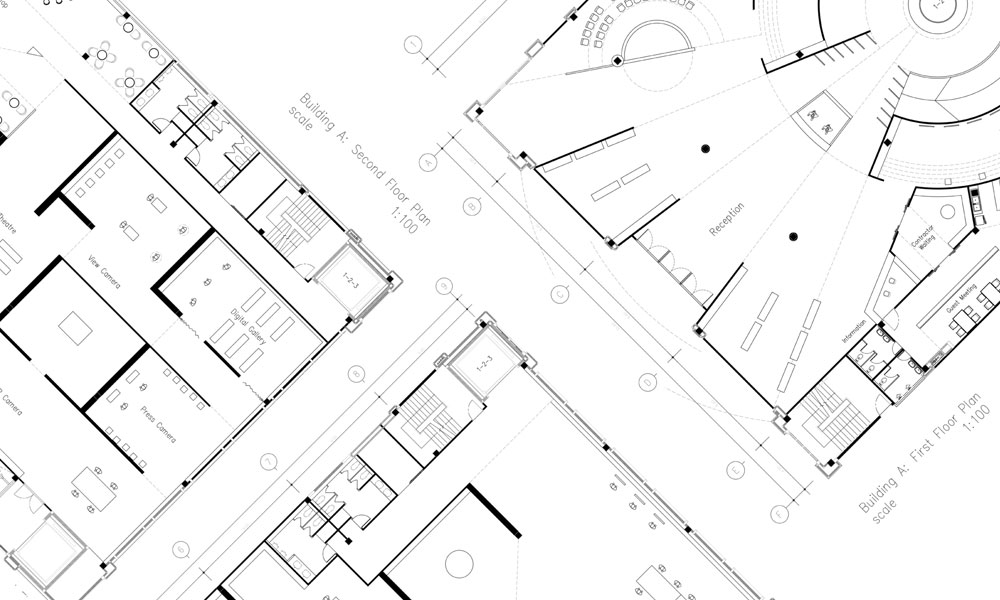

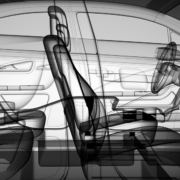

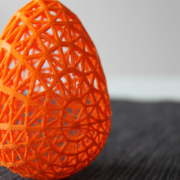

3D rendering is the process of turning information from a 3D model into a 2D image. 3D rendering can be used to create a variety of images, from the intentionally non-realistic to what’s called photorealistic. The latter look so much like images captured by a traditional camera that most consumers can’t tell the difference between a 3D rendering and a “real” photo.

Traditional Product Photography by Tom Swinnen

3D Render by @LDMartin and @momnt.uk

So, what are some of the reasons IDS uses 3D rendering over product photography?

Quick

A benefit to the client is the quick turnaround time we can provide them with renders which can help visualise what the final product will look like without having to build a full scale prototype.

Additionally, should a shot have been forgotten about or not quite come out perfectly, it can quickly and easily be rendered with the exact same lighting and environment as before. This is difficult and time consuming to do with a traditional photography setup. Also, the ability to make design changes on the fly can be a major benefit and means that should something not look quite right, a quick change can be made instead of having to remodel an entire prototype.

Flexible

One of the most convenient benefits of 3D modelling and product rendering is that we have full control over light and this is one area that shows how much more flexible rendering is. It allows for setting up lighting – their type, intensity, and warmth. Adding, removing or editing lights in CGI costs just a few clicks, and the time it takes to render a new image. Compare this to physically taking the correct lights to a shoot or even waiting for the right time of day, it is easy to see how CGI is not only quicker but also cheaper compared to traditional photography.

Cost Effective

As mentioned above, 3D rendering is cheaper than photography as cameras, lenses, environments, etc. can get very expensive, very quickly. That isn’t even taking editing/retouching of the images into consideration and then there’s travel costs, shipping costs and similar, easy to forget costs, which can build up too.

Then there are the previous benefits stated such as quick changes and no need for perfect prototypes. Plus, if it needs to be clear that there are different colour options, this can changed with a click of a button instead of spending money on multiple prototypes in each colour.

Overall, 3D rendering is much more cost effective, time efficient and provides incredible results. It is a method that benefits all parties.